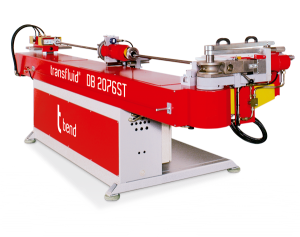

DB2076ST

Download brochure Contact opnemenDoornbuigmachine 2076ST

Capaciteit:

| Rond staal | 76,1 x 3,0 mm Ø |

| Ronde buis roestvrij staal | 76,1 x 2,0 mm Ø |

| Vierkante stalen buis | 60 x 2,5 mm |

| Vierkante stalen buis, buigas A | 60 x 40 x 3,5 mm |

| Vierkante buis zacht staal, buigas B | 40 x 60 x 3,5 mm |

| Max. weerstandsmoment | 12,1 cm³ |

| Buighoek tot | 180° + 10° terugvering |

| Buigsnelheid | 29° / sec. (voorinvoer) |

| Snelheid voorinvoer | handmatig |

| Rotatiesnelheid | handmatig |

| Nauwkeurigheid van de buigas | – |

| Nauwkeurigheid van de lengte | handmatig |

| Nauwkeurigheid van de rotatie | handmatig |

| Opnamelengte/bruikbare lengte | 4572 mm |

| Radii | max. 190 mm |

| Buighoogte | 1250 mm |

| Vermogen buigas | elektro hydraulisch |

| Automatische positionering van de rotatie en lengte | handmatig |

| Alle andere assen (bijv. klemming, doorn vooruit/achteruit, enz.) | elektro hydraulisch |

Machine-uitrusting/basisaccessoires:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Besturing:

|

|

|

|

|

|

|

|

Machinegegevens:

| Standaardnorm hydraulische componenten |

| Nominale druk 250 bar, werkdruk 200 bar |

| Bedrijfsspanning 400 Volt – 50 Cyl. – 3 Ph.- 11 KW |

| Stuurspanning: 24 VDC |

| Lengte 6800 mm |

| Breedte 1400 mm |

| Hoogte 1300 mm |

| Gewicht 3100 kg |