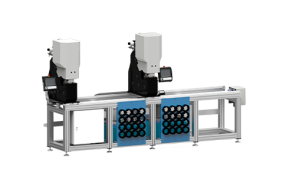

SP1200D

Download brochure Contact opnemenFINN-POWER SP1200D DOUBLE HEAD CRIMPER

FOR COMPLEX BENT HOSE ASSEMBLIES

Finn-Power SP1200D side feed crimping machine allows side feeding of the hose and crimping both ends at the same time. Automotive hose assemblies are often having complex bent shapes, which can be challenging and time consuming to crimp on traditional pass through crimpers. Finn-Power C-frame technology offers innovative solutions for this demanding use.

SP1200 has crimping force of 1200 kN, to handle automotive hose assemblies and small hydraulic hoses. State of the art ICC-control offers various features for quality control and work queues, as well as ensuring all fittings of the hose assembly will be crimped.

Control

- ICC (7″ touchscreen)

Standard features

- Quick Change-tool

- Foot pedal

- Motorized movement of second head

- Position display

- 3 meter table (other lenghts available)

- M8 groove on table profile for jig installation

Options

- Double hand operation panel

- Pressure crimping ICC1

- Step crimping ICC2

- Quality control ICC3

- Graphical quality control ICC4

- Interface pack ETH (Communication TCP/IP & UDP)

- Bar Code Reader BCR

- Auto greasing G3

- ICC 12″ display

| Technical data | |

| Crimping range (mm) 1) | 10–54 |

| Crimping range (inch) 1) | 0.39-2.12 |

| Max. crimping force (kN) | 1200 |

| Max. crimping force (tonnage) | 120 |

| Cycle time 10 mm (s) 2) | 2.1 (S-model: 1.3) |

| Hose size ID (inch) | 11/4 |

| Die set series 3) | CC22 |

| Max. opening (mm) 4) | +25/+63 |

| Master die D/L (mm) | 84/78 |

| Master die D/L (inch) | 3.31/3.07 |

| Motor Power (kW/HP) | 4.0/5.5 |

| Oil tank volume | 2 x 50 L |

| Dimensions (LxWxH) | |

| Machine (mm) | 880x3700x2086 |

| Machine (inch) | 34.6×145.6×80.0 |

| Weight (KG/LBS) | |

| 2250/4950 |

1)With standard dies. Crimping range can be increased with special dies.

2) Theoretical with 10mm cycle.

3) See table for die set data.

4) Maximum opening is the total die travel. Add this value to the minimum crimping diameter of the die set used. The result is the maximum opening of the machine with die set in place.